- Flat Labeling Machines

- Wet Glue Labeling Machine

- Hot Melt Glue Labeling Machine

- Real-time Print and Labeling Machine

- Rotary Labelling Machine

- Bottle Labeling Machines

- Side Labeling Machines

- Special Labeling Machines

- Wire & Cable Labeling Machines

- Shrink sleeve label machine

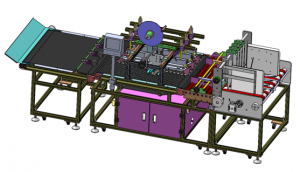

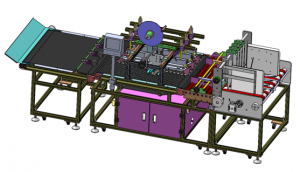

- Double side sticker labeling machine

- Labeling Machines

1. Basic use:Suitable for sticking double-sided adhesive/3M glue on the upper plane of various items, and automatically cut according to the length of the glue; such as posters, paper cards, boxes, bags, etc.;equipped with automatic feeding mechanism, automatic collection Material organization, it is more efficient to replace labor. 2. Scope…

Rent: Negotiable /day

Price: Negotiable

Contact Us1. Basic use:

Suitable for sticking double-sided adhesive/3M glue on the upper plane of various items, and automatically cut according to the length of the glue; such as posters, paper cards, boxes, bags, etc.;

equipped with automatic feeding mechanism, automatic collection Material organization, it is more efficient to replace labor.

2. Scope of application:

◆Applicable labels: double-sided tape, 3M glue;

◆Applicable products: products that require adhesive strips to be attached to a flat surface.

◆Application industry: widely used in printing, electronics, packaging and other industries.

◆Application example: poster/larger paper automatic sticking tape.

3. Working process:

◆Core working principle: the sensor detects the passing of the product, and sends back the signal to the labeling control system. After the signal is processed by PLC, the adhesive tape is sent out and attached to the set position of the product at an appropriate time, and the tape is adhered firmly , When the set labeling length is reached, the tape is automatically cut off, and the attaching action of one tape is completed.

◆Operation process: put stacked products —>automatically divide materials by manipulator —>product guide —>product inspection —>apply adhesive tape —>collect labeled products.

4. Functional characteristics:

◆Simple adjustment, configuration of front and back, left and right, up and down directions, suitable for different glue positions and different thickness products;

◆The machine has an automatic feeding function, which can automatically divide the product; and the conveying has a suction function , Can make lighter products run smoothly;

◆Touch screen control, human-computer interaction interface with operation teaching function, parameter modification is intuitive and clear, and various functions are easy to switch;

◆Intelligent control, automatic photoelectric tracking, with no objects and no labeling, to prevent tape Loss;

◆Sturdy and hygienic, mainly made of stainless steel and high-grade aluminum alloy, firm quality, in line with GMP production requirements;

◆With automatic shutdown function, production counting function, power saving function (when there is no production within the set time, the equipment will automatically switch to the province Power standby state), production number setting prompt function, parameter setting protection function (parameter setting sub-authority management), convenient for production management.

5. Technical parameters: The

following are the technical parameters of the standard model. Other special requirements and functions can be customized.

◆Applicable tape width: 5~80mm

◆Applicable product size: L (100-500) W (150-1000) H (0.2-2) MM

◆Applicable tape outer diameter (mm): φ350mm

◆Applicable tape inner diameter (mm): φ76mm

◆Labeling accuracy (mm): ±2mm

◆Conveying speed (m/min): 30m/min

◆Labeling speed (pcs/min): 50-150pcs/min (related to product size and glue size)

◆Frequency (HZ): 50HZ

◆Voltage (V): 220V

◆Power (W): about 2KW

◆ Air pressure (Mpa): 0.4-0.6

◆Equipment dimensions (mm) (length×width×height): about 3500×1350×1560