KenWei Selective Vertical Lift Modules – Automated Storage & Intelligent Retrieval Warehouse System

KenWei Selective Vertical Lift Modules with extremely fast automated storage (AS) and retrieval system (RS), are used wherever optimum use of the available room height is paramount, with which maximum of storage space can be realized on a minimal footprint. Fast provision of goods according to the goods-to-person principle shortens travel and waiting times, reduces error rates and search times in favor of high performance and high energy savings. The operation and administration of our automated shelving carousel storage is usually carried out via an integrated warehouse management system and a higher-level ERP system of the customer.

Advantages

- Better use of space available in a facility, maximize the storage capacity

- Complete the most cargo storage and retrieval work with the least manpower, time and cost

- Faster, more accurate goods removal with the highest possible picking accuracy

- Fast provision of goods and rapid tabla change

- Lower operating and maintenance costs with a long service life

- Flexible and user-friendly thanks to Windows-based interfaces

- Can be subsequently expanded with comparatively little effort in the event of capacity bottlenecks

- Can dramatically increase productivity, efficiency, and profitability for many operations in many industries

What Is Selective Vertical Lift Module (Shelf Carousel)?

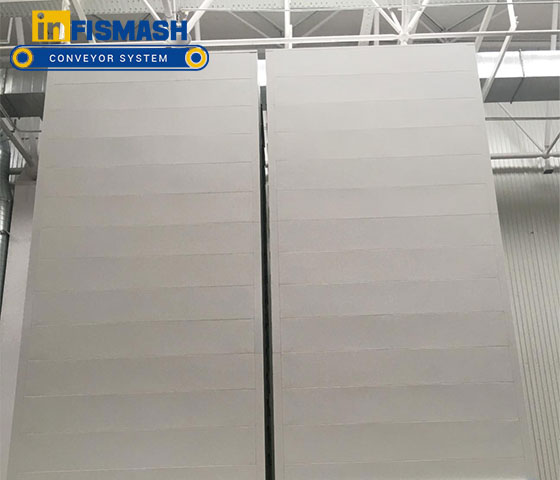

The intelligent Selective Vertical Lift Module also known as Shelf Carousel, has the same principles and functions as the tray type lift module. The storage unit is divided into several units horizontally. The width and depth of the storage unit are determined according to the size of the bin, and the bin is fixed by the supports on both sides. In addition to the function of lifting up and down movement and forward and backward translation movement of the elevator, it can realize the automatic storage and retrieval of the material box by moving the trolley in the horizontal and left directions. After the expansion of the stand-alone equipment, Automated Shelving Carousel can realize online operation, docking with the conveying line, and realize the storage and retrieval of batch unit bins, and transport the bins to the instruction station through AGV or robots, thereby realizing unmanned operation. Greatly improve work efficiency and reduce production logistics operating costs. At the same time, the system will automatically record the quantity of materials and the location of the storage unit to facilitate query, traceability and automatic inventory.

Shelf Positioning, Picking & Transferring System

The intelligent selectable vertical lifting system uses the material box as the storage unit, adopts a modular design, multiple rows or multiple layers, and effectively realizes the dense storage of materials. The fully enclosed design adopts constant temperature and humidity to meet the needs of different customers. The first mode is the docking mode between the equipment and the conveyor line and the AGV trolley, the second is the docking mode between the equipment and the conveyor line and the third is the online operation of the equipment. Realize unmanned operations such as intelligent warehousing, logistics and transshipment, and the products are widely used in the field of factory spare parts and electronic product file management and other fields.

KenWei self picking storage lift is highly customizable and can be optimally adapted to the respective operating environment. In the standard version it offers the following features and advantages: