Is your facility bursting at the seams? Are you struggling to get orders out on time? An automated storage and retrieval system could be your optimal solution, these intelligent systems that automatically stage and retrieve inventory within a distribution facility or manufacturing operation can give your throughput a massive overhaul, all while recovering much-needed floor space and allowing you to continue in your current building. But due to some misconceptions, many DC operators believe ASRS isn’t right for their facility. In this guide, we will tell you how does an automated storage and retrieval system work to help you actually save money and delivers incredible ROI.

What is Automated Storage and Retrieval System?

What is the definition of an automated storage/retrieval system? Automated storage and retrieval systems known as ASRS are software-controlled systems that automatically place and retrieve inventory within your facility with precision, accuracy, and speed, increasing your throughput and minimizing your waste, and they are the key to increasing throughput.

How Does a Automated Storage and Retrieval System Work?

Automated storage and retrieval systems can be combined in a multitude of ways to create solutions that match any application:

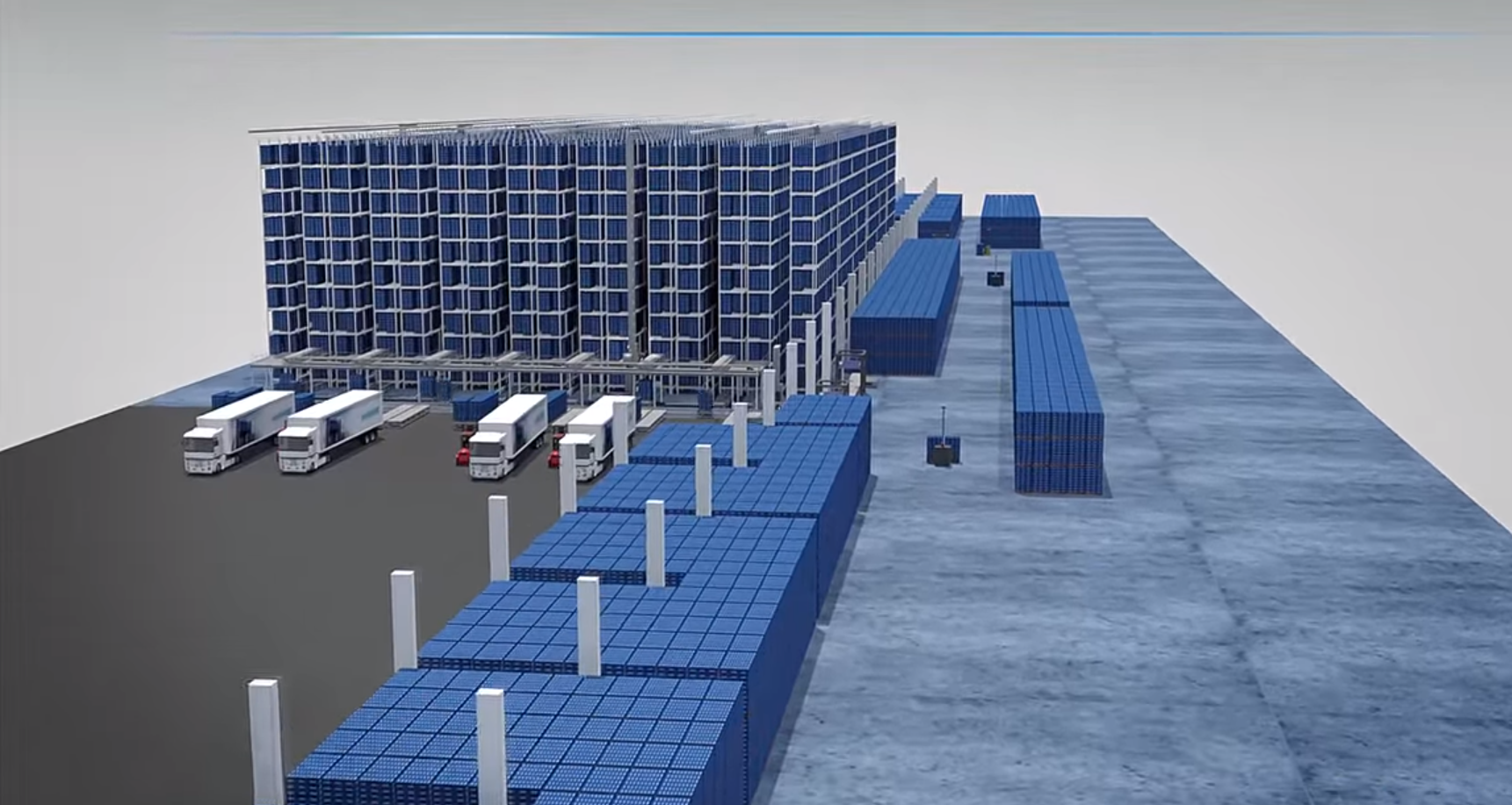

- Unit loads are machines that store large loads usually more than a thousand pounds, these loads are stored single deep, double deep, or even deeper and are typically on pallets with storage rack structure reaching over 100 feet.

- Operating the same way, a mini load handles loads weighing less than a thousand pounds.

- Vertical lift modules consist of a column of trays with an automatic insert or extractor to retrieve items that are stacked vertically.

- Shuttles are used for the automated handling of totes, trays, cartons, or all three in the same system.

- Horizontal carousels are ideal for storing small parts and pieces, they’re comprised of a series of bins that rotate horizontally around a track.

- Vertical carousels rotated vertically like a ferris wheel, housing a series of shelves or couriers to provide high-density storage

- Cube based storage is an ultra high density goods two-person piece picking system, utilizing robots to store and retrieve inventory bins from a cubicle storage grid.

Advantages of Using AS/RS

AS/RS integrates with Warehouse Execution Software (WES), Warehouse Management Software (WMS), and other business systems. The AS / RS implementation enables warehouses and distribution centers to deliver the following main benefits:

- Increasing speed: Automated systems take advantage of optimal routes that further increase the efficiency of product selection and also accelerate order fulfillment. The online retailer uses robots and conveyors that greatly increase the speed of order fulfillment. Because of this, they may offer free overnight shipping; A great competitive advantage in the industry.

- Decreasing cost: With warehouse automation, the retailer can keep their machines running for a long time without incurring additional cost. A cost that would mean having employees working, for example, in high season.

- Maximize space: it is one of the most important advantages that automation offers. Space is a finite resource, especially in warehousing and distribution facilities that are packed with all kinds of goods.

- Traffic flow optimization: warehouse signs can be used to provide traffic signs and other information to speed up the flow of goods through the facility. While optimizing traffic flow by avoiding congestion in the aisles, helping workers optimize time.

- Automatic replenishment: when items are automatically tracked with barcode labels and data is synchronized in real time with a WMS, out-of-stock situations can be completely mitigated by activating replenishment systems. These commands cause the automatic reordering of the inventory when the stock reaches a previous level. Low threshold defined.

FAQs For Automated Storage and Retrieval System (AS/RS)

Ecommerce is driving the need for single item picking, but most distribution centers don’t have the infrastructure to keep up with the trend and stay relevant, due to some misconceptions many DC operators believe ASRS isn’t right for their facility. By answering the following frequently asked questions, you will have a deeper understanding of AS/RS.

How Does Automated Storage and Retrieval System (AS/RS) Save Cost?

But many facility managers are afraid of the perceived price tag. The truth is ASRS delivers incredible return on investment, providing immediate and long-term savings. How can that be? Well, most facility managers are just looking at the face value of the system and not taking into account the host of other costs that ASRS reduces. The cost savings that ASRS brings to the following areas will ensure a very high return on investment:

- Save Cost for Space

If your facility is cramped, you’re probably thinking about expanding your current space or even building a new space from the ground up, how much would that cost? On the other hand ASRS is extremely high density and configurable to any space, meaning you can greatly extend the life of a facility that you think you’ve already outgrown, that also means less money spent on land or rent and less opportunity cost from things like construction.

- Save Cost For Workforce

The workforce shortage is an increasing issue our aging and educated population is less interested in manual labour, and a specialists for qualified labor are extremely hard to find and require high compensation. ASRS drastically reduces the need for unqualified labor because picks, especially under canonic picks at high and low elevations are automated, that means less money spent on workplace injury claims. And ASRS also reduces the need for qualified workers, because the systems are so easy to learn and use, the systems can be learned in days weeks by someone with little to no previous knowledge. And because of the high visibility and audit trail the systems provide costs for quality control and security can be reduced as well.

- Save Cost For Energy

Because ASRS is ultra high density and requires little to no worker intervention, installing a system can save you money on lighting, heating, and cooling for a large space designed for humans. ASRS compatibility with these harsh environments means that they also have exciting applications in cold storage and that’s not the only way ASRS units save energy. Many systems actually harness kinetic energy from their descending motions and recycle that energy for ascending motions.

So if you’re thinking about building a facility, knocking down a wall or hiring more team members, ask yourself what would that cost your business, is that option truly scalable? The better question might be “can you afford the cost of not implementing a future ready ASRS”. When you consider the ROI and ASRS is much more affordable than continuing with a manual operation. To see which ASRS is the optimal solution for your facility visit our website and schedule a consultation with us.

What Companies Use Automated Storage and Retrieval System (AS/RS)?

Businesses of all types and sizes – from retailers, manufacturers, and grocery stores to producers of high-value or regulated items (such as medical devices and pharmaceuticals) – benefit from AS / RS adoption.

Does AS/RS Fit in a Small or Oddly Shaped Space?

The first myth is that ASRS is too big for small spaces. The truth is that an ASRS is always tailored to your space, so whether your DC is a massive warehouse in the suburbs or an oddly shaped building sandwiched in downtown of a big city, there’s a system to meet your specific application. In fact, because ASRS transcends storage, it will actually save space. Because picking is automated, items are stored at a much higher density, items can be stored at very high and low physicians that would not be safe or economics people to reach, and specific storage positions can even accommodate fast movers.

Can AS/RS Accommodate Oddly Shaped Items?

Some believe that ASRS is not compatible for oddly shaped items. The truth is that it doesn’t matter what size or shape your items are, ASRS units can be configured to facilitate single item picking for items as small as jewelry, or store and pick pallets with loads heavier than a thousand pounds like furniture.

Can AS/RS Be Communicated with Existing Equipment System?

Many believe that the new ASRS won’t communicate with their existing equipment or software. The truth is that most systems today are standardized, ASRS integrates swiftly into your existing ERP, WM, WCS, or WES. And you’ll be up and running in no time, this also means that it’s easy to reconfigure when you want to expand your system.

What Will AS/RS Happen If Power Goes Out?

DC operators worry about what will happen to the ASRS if the power goes out. The truth is if your power is compromised, your ASRS will probably be the last thing to shut down, since they can be backed out by external generators. But in the unlikely event that every last system in your DC, including the lights shuts off would it really be safe to have employees picking from racks in the dark probably not. Luckily it’s easy to keep your ASRS in peak working condition, because there’s 24/7 maintenance support available through the provider.

So now that you know the truth what are the next steps in creating your newly powered up supply chain, decide what items you want to store and move measured your floor space ceiling height and item size, and get in touch with us, we will work with you to create your optimal solution.

KenWei Automation is the industry’s leading supplier of automated storage and retrieval systems, we supply these systems and solutions to virtually every major manufacturing retail and distribution sector. We have the combined experience from thousands of installations and access to a massive body of knowledge and resources, and use this expertise to optimize safety innovation and peak performance get ahead of the curve and manage demand increase your throughput and revolutionize your business with automated storage and retrieval systems.