As we all know, automatic sorting machine it can automatically sort, box and seal strips of cigarettes, full cartons of cigarettes, drugs, goods, materials, etc. Automated storage and automated sorting are different operating systems, but both are different parts of the automation industry. According to user, place name and name in a continuous operation according to the user’s requirements and site conditions. Although automatic sorting machines have made great contributions to the warehousing and logistics industry, it does not mean that automatic sorting machines are without drawbacks. In this article, we will introduce the advantages and disadvantages of automatic sorting machines in the hope that you can take an objective look at them.

Advantages of Automatic Sorting Machines

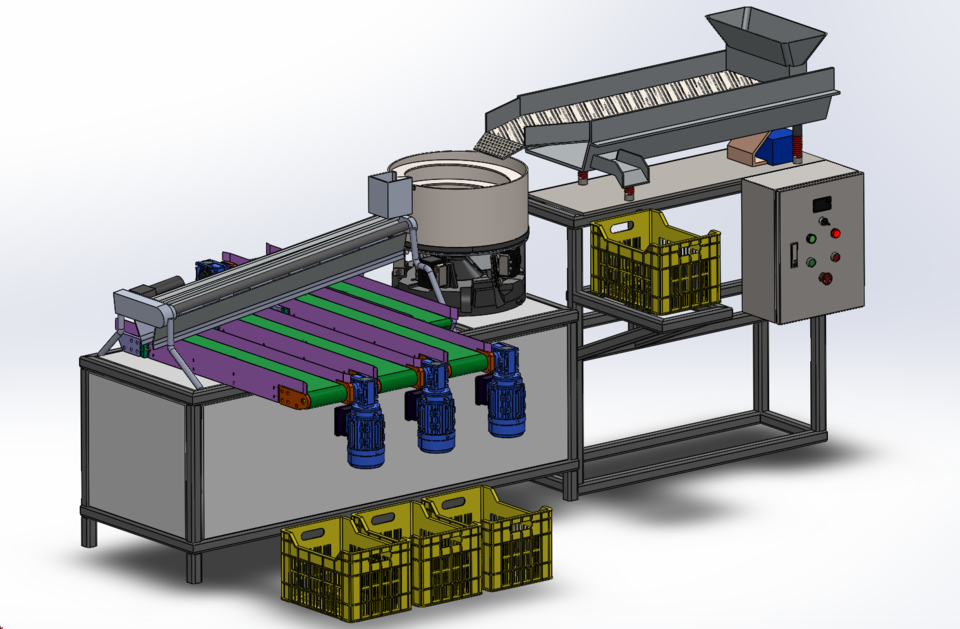

- Automated sorting: Sorting systems are applied to equipment that can control the equipment to automatically sort goods without the need for manual sorting. Automated sorting reduces a lot of labor costs for companies, while also speeding up their work and making it easier for them to manage stored goods. In addition, companies do not need to spend more time on sorting work and can place their efforts on other tasks.

- Data storage: The sorting system can store data while it is working, and this data is stored in the system. The main purpose of data storage is to ensure that the goods are sorted correctly and that the sorted goods are not lost. When sorting goods manually, there are often sorting errors or lost goods, leading to a variety of problems in sorting. Therefore, sorting system data storage can effectively avoid such problems.

- Cargo Safety: The use of equipment for sorting goods ensures that the goods are sorted safely and correctly. However, manual sorting of goods can lead to various problems, especially the safety of goods cannot be guaranteed.

- High sorting efficiency: The high efficiency of sorting is the biggest advantage of the system application, so every company is willing to use the sorting system to achieve efficient sorting.

Disadvantages of automatic sorting machines

Similar to the general environment of the entire logistics industry, China is still relatively backward in terms of automatic sorting machines compared to developed countries, and manual work is still relatively common. The production and use of auxiliary picking systems such as electronic tags and RF technology are not yet abundant, and there are even fewer automatic picking systems. In general, the application of automatic sorting machines in China shows a low degree of intensification, and the application of automated systems and equipment is not widely used.

There are many factors that hinder the development of automatic sorting machines, some of which are consistent with the problems that exist in China’s logistics industry as a whole. Logistics standardization is one of the long-term concerns of China’s logistics industry. Bar coding of commodities, standardization of packaging, etc. is a guarantee for the smooth operation of automated picking systems, and in China, the commercial system has not yet seriously studied the use of automated sorting machines because there are basically no printed bar codes on commodity boxes (meaning shipping packaging). In addition, since one company or enterprise often cannot influence the progress of the whole industry, some large enterprises tend to develop systems that suit their own business characteristics, which further creates obstacles to interface in practice. The issue of the price of automation equipment and systems is another impediment, with small businesses generally unable to afford to purchase high-priced equipment.