Lean Lift

Over 60% greater space

The Lean-Lift makes use of the reachable room top – in a similar way to a high-bay warehouse or miniload system. Unlike these, however, it shops components in top optimized positions so that no area is lost. This produces most storage potential on a minimal footprint. This in flip saves charges and helps to utilize the location committed to storage extra economically.

Efficiency

Countless corporations at some stage in the world use the Infismash Lean-Lift to make bigger the cost-effectiveness of their warehousing and substances handling. Hänel additionally presents custom-made one of a kind elements to get even greater effectivity out of the Lean-Lift.

Ergonomic and safe

The ergonomic design minimizes the physical strain of employees at work. Infismash goes far beyond the requirements of today’s security standards.

working time is saved

Lean-Lift automatically brings desired items to the access area in seconds and retrieves them at an ergonomically optimal height. Goods to man is a motto, not man to goods. Access times are drastically reduced and order picking performance is dramatically improved.

Optimal Parts Management

The present day Infismash microprocessor controller can be used as a stand-alone stock administration device or speak with the customer’s very own statistics processing system. Always make certain an up to date stock overview.

Infismash Lean-Lift models

Infismash Shuttle 250

Flexible solution for small parts and lightweight inventory.

The Infismash Shuttle 250 is a solution for storing and retrieving small-sized inventory. With a tray width of 2,600 mm, the Infismash Shuttle 250 can cope withmasses up to 250 kg per tray. It’s compact layoutlets in it to adapt to area requirements, impartingmost storage potential in a minimal footprint with a mosttop of eight m. Further, the devicewithout problems modifies to a largevary of requirements. For example, for storing items in temperature manageddevices or underneatheasy room conditions.

Infismash Shuttle 500

Highly compact storage for medium loads

The Infismash Shuttle 500 zhandles a tray width of 2,600 mm and hundreds up to five hundred kg per tray. It adjusts to a machine top of 12 m permitting a massive storage volume. The Infismash Shuttle five hundred is best for correctly storing and retrieving heavy tools, factors or spare parts. It is extraordinarily bendy with a wide variety of unique alternatives that can be effortlessly built-in earlier than or after installation. The devices can expand, decrease, alter or adapt in a variety of approaches to cater to altering wants which includes commercial enterprise growth, new applications, or a relocation.

Infismash Shuttle 1000

Manages heavy duty loads up to 1,000 kg

With a tray width of 2,600 mm, the Infismash Shuttle 1000 hundreds up to 1,000 kg per tray. Achieving new load-carrying ability standards, it is perfect for storing medium-heavy to heavy parts. Using a forklift, stack and keep Euro pallets and mesh packing containers in specifically designed trays. This saves area and makes it viable to discover items faster, supporting to decrease costs, increase productiveness and extend ergonomics. A factory-installed crane can be used to go saved items easily, reducing working instances and costs.

Every Infismash Shuttle is configured to meet your needs

Technical data of the Vertical Lift Module

| Shuttle 250 | Shuttle 500 | Shuttle 1000 | |

| Width | 1,706 to 3,456mm | 1,706 to 3,456mm | 1,706 to 3,456mm |

| Depth | 2,341 and 3,100mm | 2,341 and 3,100mm | 2,341 and 3,100mm |

| Height | 2,550 to 12,000 mm | 2,550 to 12,000 mm | 2,550 to 12,000 mm |

| Load | Up to 250 kg | Up to 500 kg | Up to 1,000 kg |

| Height grid | 100 mm | 100 mm | 100 mm |

The values are shown in the table reference standard configurations. It is possible to also construct other units with different widths, depths and heights.

Additional options

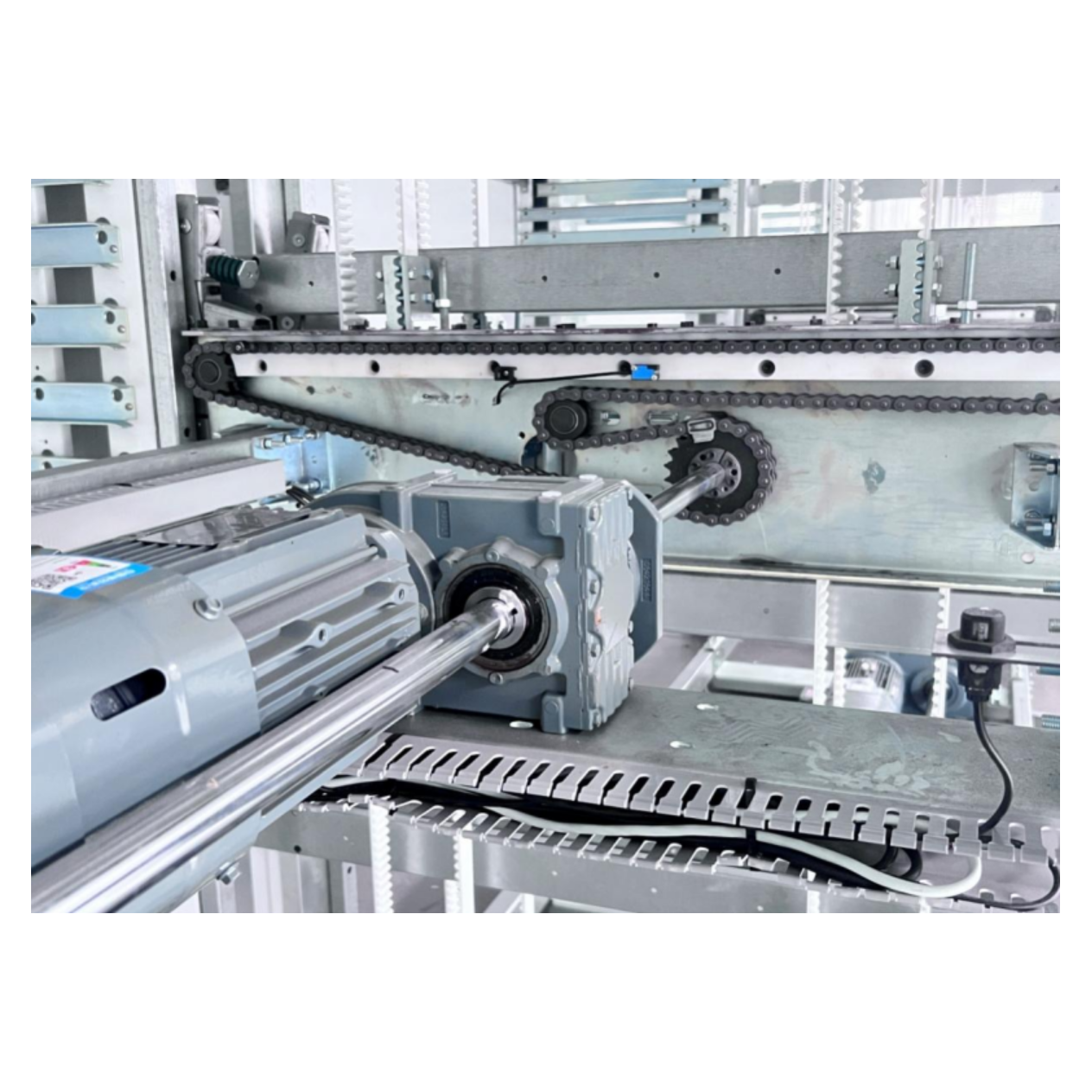

High-speed lifting drives↗

multifunction containers↗

Access Port ↗